Krones boosts production efficiency in data center and executes safe migration from RISC platforms for mission-critical applications

Here's a great story about the Machinery and Engineering company Krones Group, out of Neutraubling, Germany. The company manufactures machinery and complete plants for process, bottling, and packaging technology.

Here's a great story about the Machinery and Engineering company Krones Group, out of Neutraubling, Germany. The company manufactures machinery and complete plants for process, bottling, and packaging technology.

Millions of bottles, cans, and specially shaped containers are processed daily on behalf of breweries, the soft-drink sector, and manufacturers of wine, sparkling wine, and spirits as well as for the chemical, pharmaceutical, and cosmetics industry.

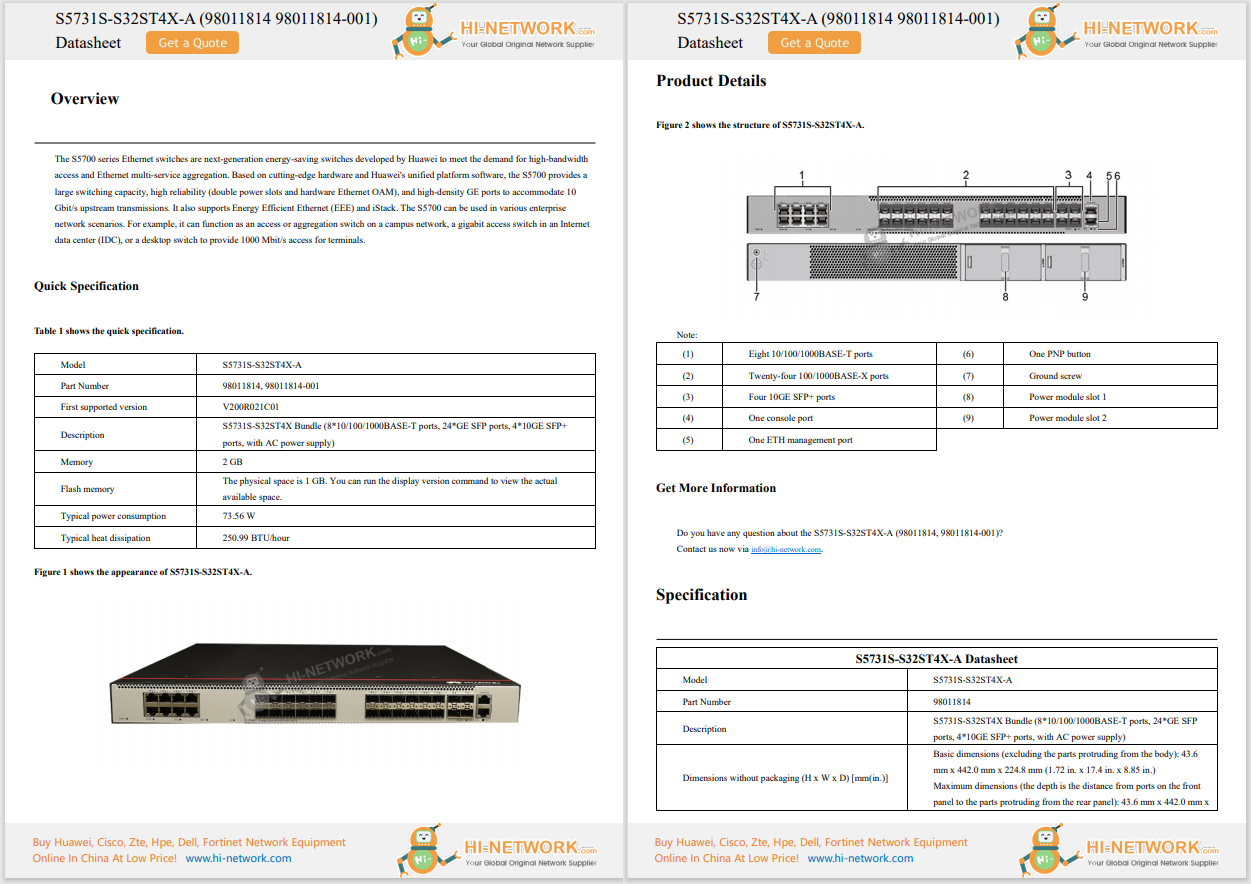

The company's data centers are a key enabler for business growth. Consisting of 200 physical servers and 700 virtual machines spread across three locations, this critical infrastructure previously used a mix of technologies from different vendors. During a typical day, the three facilities handle around 1.3 petabytes of data and, in the case of the largest SAP database with more than 6TB, serve 5500 users concurrently. This data center environment relied on reduced instruction set computer (RISC) processor architectures for business critical applications such as SAP and databases, mostly running Solaris operating systems.

The company's data centers are a key enabler for business growth. Consisting of 200 physical servers and 700 virtual machines spread across three locations, this critical infrastructure previously used a mix of technologies from different vendors. During a typical day, the three facilities handle around 1.3 petabytes of data and, in the case of the largest SAP database with more than 6TB, serve 5500 users concurrently. This data center environment relied on reduced instruction set computer (RISC) processor architectures for business critical applications such as SAP and databases, mostly running Solaris operating systems.

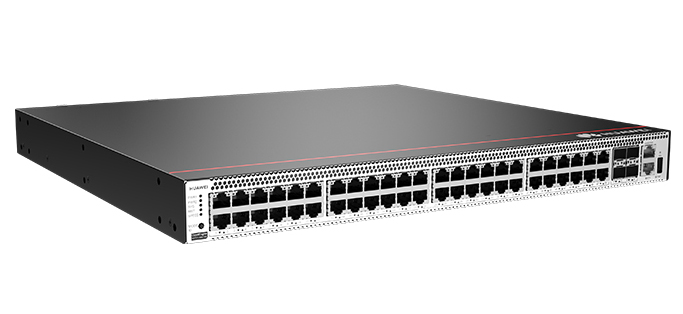

Krones selected a Cisco Smart+Connected? Manufacturing solution, based on the Cisco? Unified Data Center. This pre-validated architectural approach combines server respective computing performance, network, and management into a platform designed to automate IT as a service across physical and virtual environments. The end result is increased budget efficiency, more agile business responsiveness, and simplified IT operations.

At the heart of the solution are Cisco Unified Computing System? (UCS?) B-Series Blade Servers, which run numerous standard server software along with a host of Oracle databases, SAP systems, and Microsoft applications including SQL server, Active Directory, Exchange, SharePoint, and Citrix.

At the heart of the solution are Cisco Unified Computing System? (UCS?) B-Series Blade Servers, which run numerous standard server software along with a host of Oracle databases, SAP systems, and Microsoft applications including SQL server, Active Directory, Exchange, SharePoint, and Citrix.

Migration from RISC/Solaris to Cisco UCS/Linux has begun and is already improving agility. IT infrastructure can now respond quicker to changes andrequirements in the development of application and business processes.

"Our Cisco Smart+Connected Manufacturing solution gives us high-speed connectivity and high-availability, while providing more flexible provisioning of computing power using central capacity management,"saysGerd Neuland, team leader IM-RZ."With Cisco UCS, for example,time to install a blade server has decreased by a factor of 10 compared with conventional rack-mount systems."

Due to complete in 2015, the planned migration from all RISC/Solaris systems to Cisco UCS/Linux will help enable Krones to adapt faster to changes in the business environment, while also delivering IT resources more effectively and efficiently.

Krones is already looking to take advantage of its Cisco Unified Data Center architecture. The extra density provided by the UCS blade servers will help to accelerate a planned SAP ERP migration.

"Our initial estimates were based upon 350,000 SAPS, but with our Cisco UCS solution, we can scale to 600,000 if we need to,"says Neuland.

What do you say? Read more by clicking on this link. And give us your comments -is this something you could use, and more to a more flexible and cost effective solution for your manufacturing Data Center?

Hot Tags :

Data Center

engineering

Manufacturing Industry

Case Study

migration

Germany

Cisco Unified Data Center

krones group

data centre

Hot Tags :

Data Center

engineering

Manufacturing Industry

Case Study

migration

Germany

Cisco Unified Data Center

krones group

data centre