Manufacturing customers are already gaining insight from IoT data by securely connecting machines and sensors. One example of this is the Israel-based manufacturer Lordan.

Lordan is a manufacturer of thermal-engineering heating and cooling systems and has a global reputation for delivering high-quality custom made designs.

Their Challenge

Lordan needed a manufacturing automation system that could identify bottlenecks, reduce downtime and waste, and improve overall equipment effectiveness (OEE). Requirements included the ability to view overall throughput and track mission-critical manufacturing information in real time directly from the production floor, rather than relying on periodical assessments.

What they wanted was a window into production that would enable them to improve inefficiencies within the plant -a system allowing end to end visibility.

The results were immediate.

In addition, they were able to:

Amir Aloni, CEO of Leadermes.com, explained why security was top of mind:

"Security issues regarding data connectivity to the cloud have been of the utmost concern to our customers in traditional manufacturing industries. This challenge prevented many manufacturers from moving to a digital factory and optimizing production efficiency. Our partnership with Cisco helped us create a unique industrial data connectivity tool, eliminating the security risks involved in cloud-based data transfer and is enabling us to provide a smart, scalable, plug and play solution with very fast deployment and reduced installation costs."

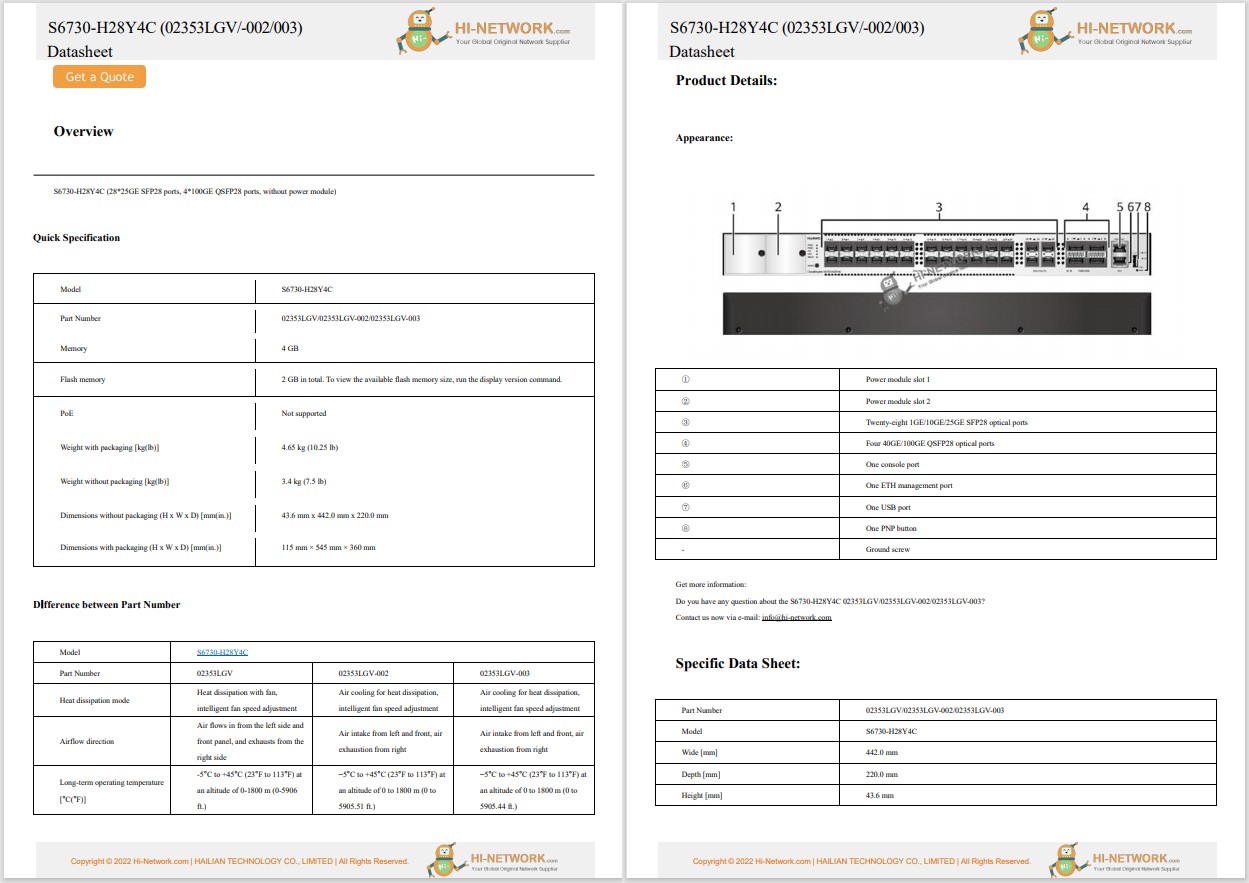

Lordan installed the following solution:

The Cisco AS Solution Validation team (SVS) approached the development of this use case with three major building blocks:

This is made possible using Cisco's Connected Factory architecture. View the full case study here.

Hot Tags :

Cybersecurity

Internet of Things (IoT)

Digital Transformation

Cisco Industrial IoT (IIoT)

Digital Manufacturing

Industrial Automation

connected factory

digital factory

leaderMES

Hot Tags :

Cybersecurity

Internet of Things (IoT)

Digital Transformation

Cisco Industrial IoT (IIoT)

Digital Manufacturing

Industrial Automation

connected factory

digital factory

leaderMES