L to R: David Ashley and Marco CrociThis post was written by David Ashley,Senior Vice President, Product & Component Operations at Cisco and Marco Croci, Senior Vice President, Engineering at Cisco.

L to R: David Ashley and Marco CrociThis post was written by David Ashley,Senior Vice President, Product & Component Operations at Cisco and Marco Croci, Senior Vice President, Engineering at Cisco. In 2018,we announced our first plastic-related goal: to reduce our use of virgin plastic by 20% by our fiscal year 2025.* We exceeded this goal in our fiscal year 2021. To build on this momentum and to address thewell-documented challenges associated with plastic, we want to share our strategy to further reduce our use of virgin plastic in our products and packaging.

We have set a goal that by our fiscal year 2025, 50% of the plastic used in our products (by weight) will be made of recycled content.**Most plastic used in Cisco products is found in a few product categories: Cisco IP phones, Webex collaboration devices, access points, and Cisco Meraki products.

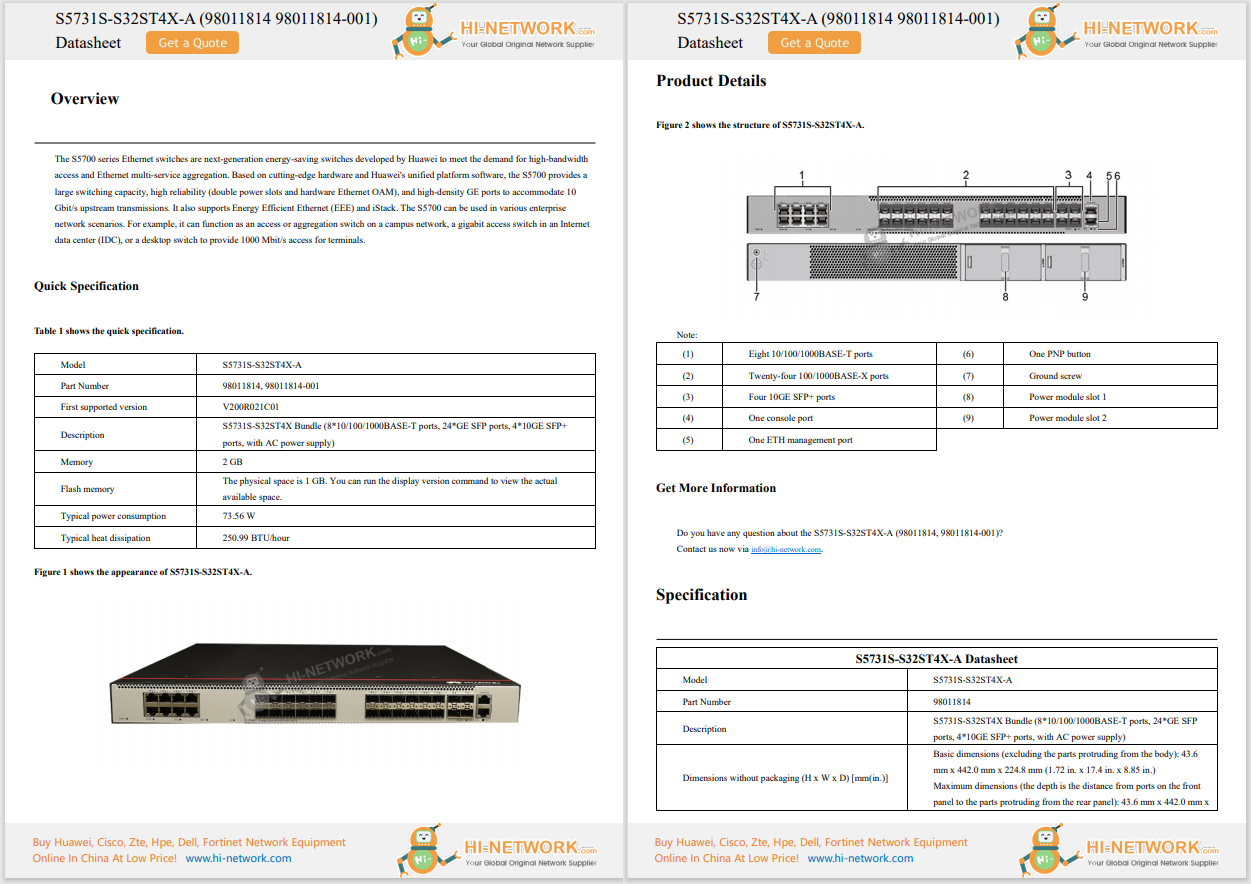

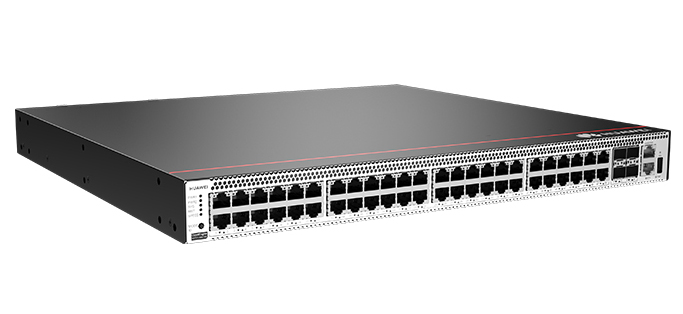

As part of our journey to minimize the use of virgin plastic, our teams are sourcing more recycled plastic parts and designing plastic out of our products. For example, select models of our 8800 Series IP phones consist of 68% recycled plastic and some products in our Catalyst series of network switches were designed without bezels, the plastic cosmetic surface on the outside of a device.

We are rethinking product packaging and are sourcing alternative materials to plastic. Our strategy includes eliminating plastic bags in our packaging wherever possible. In our fiscal year 2022,the majority ofaccessoriesforCisco Meraki products shippedin paper-based packaging, which was made of 70% recycled content. And in certain other product lines, power cords are labeled with scannable wraps instead of plastic bags. As a result of these changes, we avoided shipping an estimated ten million plastic bags, representing 28 tonnes of plastic.

Furthermore, we are continuing to reduce foam packaging, another material made from plastic. The packaging for the Catalyst IR8140 Heavy Duty Router is the first solution at Cisco to use a fiber-flute material in place of the foam cushioning that is typically required for heavier products. Opportunities to minimize the use of foam across our product portfolio will help us reach our goal of reducing our use of foam packaging by 75% by our fiscal year 2025.***

Addressing plastic is just one part of our holistic circular design strategy, which is focused on designing products and packaging with reuse and resource efficiency in mind. We have set a goal of incorporating Circular Design Principles into the design of all new products and packaging by fiscal 2025. To do this, we are embedding circular design requirements into our design tools and product development processes, including engaging our suppliers on innovative, sustainable designs for our products, components, and packaging.

We are also working to avoid shipping unwanted accessories to customers by integrating accessory selection into the ordering process. In our fiscal year 2022, over 8,500 customer orders opted out of receiving a power cord, avoiding the shipment of approximately 205,000 unnecessary power cords, as well as minimizing the packaging that would have wrapped them.

We are committed to designing products and systems that help to enable reuse, minimize environmental impact, and realize value for our stakeholders. We look forward to continuing to share our progress towards these goals along the way.

Footnotes

* Compared to a fiscal 2018 base year.

** The plastics included in this goal exclude those contained in commodity components sourced from suppliers (e.g., plastic screws, fans, and cables).

*** Compared to a fiscal 2019 base year; goal is measured by weight.

Forward Looking Statements:Readers are cautioned that this blog post may be deemed to contain forward-looking statements that are subject to risks, uncertainties, assumptions and other factors that are difficult to predict, including those factors identified in our most recent filings with the Securities and Exchange Commission on Form 10-K and Form 10-Q. Such information speaks only as of the date of this blog post. For further information, seeForward Looking Statements.

Hot Tags :

Featured

Corporate Social Responsibility (CSR)

environmental sustainability

Chief Sustainability Office

circular economy

Hot Tags :

Featured

Corporate Social Responsibility (CSR)

environmental sustainability

Chief Sustainability Office

circular economy