Sir James Dyson, British inventor, industrial designer and founder of the Dyson Company once said, "Manufacturing is more than just putting parts together. It's coming up with ideas, testing principles and perfecting the engineering, as well as final assembly." He's absolutely right; manufacturing is more than just manual labor on a shop floor somewhere. Today's manufacturing jobs require a new wave of skilled employees, but where are they?

It amazes me to think about how far manufacturing in the U.S. has come since the days of the industrial revolution and all the way up through the 1950's. Fast forward to today and you'll see a manufacturing industry that now relies on advances in technology to drive production and help fuel a global economy. In fact, my colleague Chet Namboodri in his blog 'Manufacturing Predictions for 2015' mentions that advancements and adoption of industrial robotics will rapidly advance across all manufacturing segments. However, the longstanding perception of manufacturing has been one of harsh work environments, something that is no longer the case in many manufacturing plants. This outdated perception must be laid to rest and changed amongst a new, younger generation of tech-savvy workers because it's discouraging qualified candidates from pursuing lucrative careers in manufacturing and directly impacting production in the U.S., a trend that could cause a largely diminished manufacturing workforce by 2030.

The New Manufacturing Environment

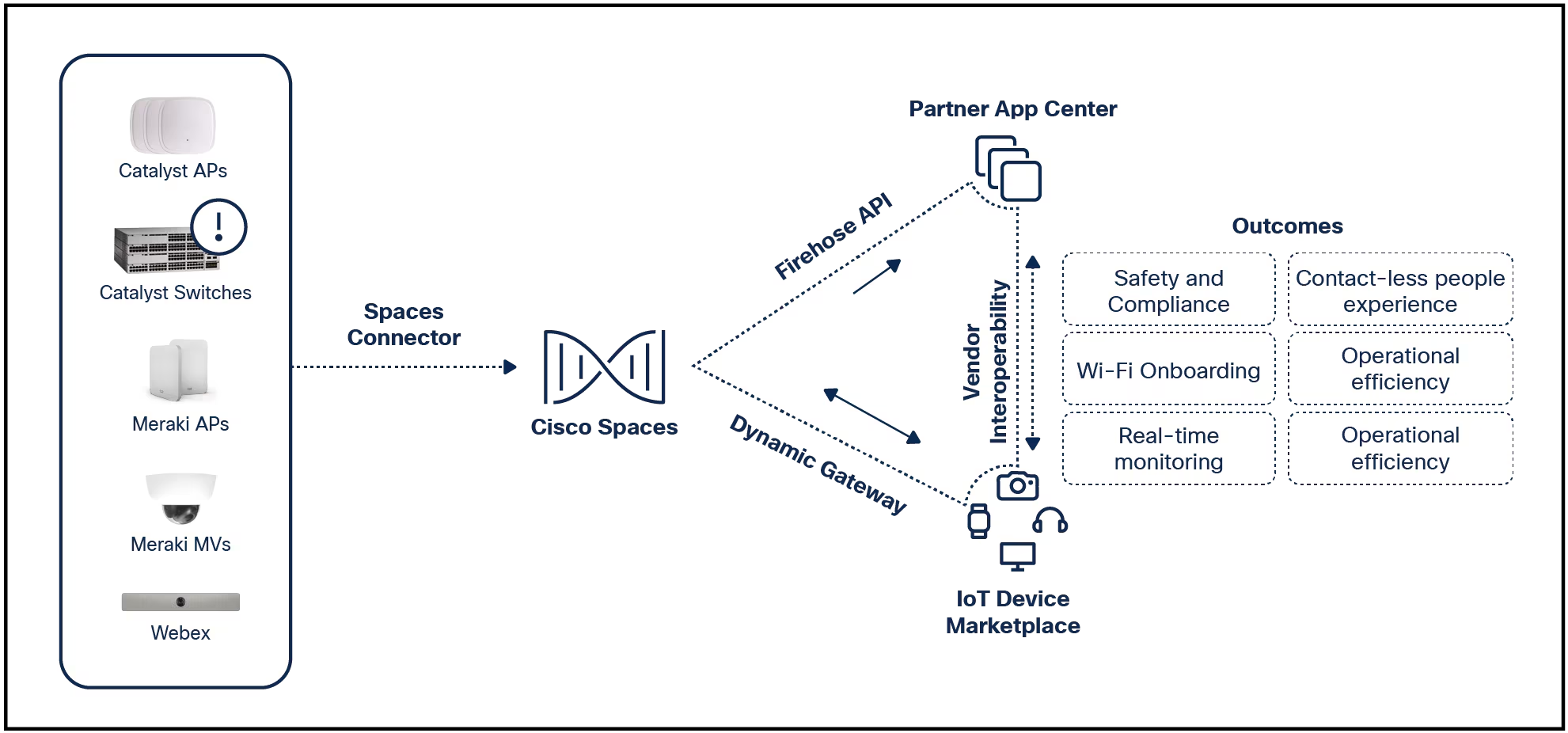

Overall, the manufacturing industry is more productive, efficient, and poised for new technological advances made possible by the Internet of Things (IoT). In the 1950s, long, tedious business and production processes created a labor-intensive manufacturing industry. Employees worked in difficult and hazardous environments every day. But as technology advanced, so did manufacturing. A lot of manufacturing jobs are no longer traditional assembly line roles and an industry once driven by manual labor is now moving forward at a much faster pace thanks to machine automation, information technology, and increased plant floor communications. Operators now require advanced knowledge of computers, software, science, and math to program machines that control manufacturing processes.

The manufacturing industry in the U.S. faces a workforce crisis as a widening skills gap is created as many workers reach the age of retirement. If current trends continue, U.S. manufacturers will be unable to fill 2 million manufacturing jobs by 2025, due to a worsening shortage of required skills, according to a report by the Manufacturing Institute and Deloitte. Today, there are really good, well-paying positions that need to be filled across the manufacturing industry. Many students and new graduates fail to consider manufacturing on their quest to find a career path -something that must change. Manufacturers must begin engaging local high schools and trade schools to enhance pipelines of Science, Technology, Engineering and Mathematics (STEM) trained graduates and developing strategies to attract qualified candidates as they enter the workforce.

Attracting the Next Generation of Manufacturers

The next generation of workers expects to always be connected. They have multiple mobile devices and interact with peers in new ways all the time. This inherent skillset can be a great asset to the manufacturing industry and with the advance of IoT, there will be a strong need for a STEM ready workforce. To generate interest in STEM and perhaps a career in manufacturing, educators must start early. Starting in elementary school, up through high school and college, career relevant math, science and computer instruction should be made available to a wider audience of students across age groups, demographics and geographies.

Not only are more skilled and tech-savvy workers needed put part of the manufacturing skills gap is the result of a lack of women in manufacturing. In fact, women have become an underutilized resource in STEM careers in general -something else that also must change. Pa. Women make up half of the U.S. workforce, but less than a quarter of manufacturing (STEM) jobs are held by women. How can manufacturers attract women to the industry and fill the current skills and gender gaps?

It starts with education. We need to educate young women about what a career in manufacturing is actually about, without continuing the negative perception of work environments. We can do this by supporting STEM education with programs that give kids practical hands-on experience. This is best accomplished when manufacturing industry leaders and organizations reach out to students and new grads, and encourage government leaders to invest in the right kind of training experiences in school curriculum.

IoT World Forum Young Women's Innovation Grand Challenge

Cisco is helping to educate young women about STEM careers through the IoT World Forum Young Women's Innovation Grand Challenge . The initiative is a global innovation challenge open to young women between the ages of 13-18. The aim of the challenge is to recognize, promote, and reward young innovators as they come up with new uses for Internet of Things technologies and is open now through May 18th, 2015. You can learn more about the IoT World Forum Young Women's Innovation Grand Challenge here.

Whether next-generation workers seek a traditional college experience or vocational schooling, students must be exposed to the various options and training opportunities that are available in the manufacturing industry. Organizations should position themselves as go-to resources for prospects looking for jobs in manufacturing. They should offer internships and be able to connect future employees to employers. Hosting workshops, seminars, and conferences are also good forums to make connections.

Through these types of experiences, we can allow students and educational professionals to build passion for the manufacturing industry. In turn, the necessary skillsets will follow. The next-generation techniques and technologies on the plant floor will entice the new age of tech-savvy students. We need solutions now for the workforce of tomorrow and we are the advocates of manufacturing's next generation workforce. Let me know your ideas in the comments below on how we can all make a difference on this issue.

Hot Tags :

Internet of Everything (IOE)

IoE

Manufacturing

operations

#MFG

Real-Time Location System

Real-time locating systems (RTLS)

Hot Tags :

Internet of Everything (IOE)

IoE

Manufacturing

operations

#MFG

Real-Time Location System

Real-time locating systems (RTLS)